Hole Plugging in an Active Surge Shaft

In 2010 Hibbard Inshore was contracted to provide an inspection of the surge shaft at the Tala Hydroelectric facility. During this inspection they were able to identify several holes with active flow in the bottom of the concrete surge shaft. This discovery was of concern to the owner as they were afraid that this may eventually affect the stability of the structure. Shortly after the inspection, the plant owner, the construction company responsible for the construction of the surge shaft, and Hibbard Inshore all proactively looked for solutions to permanently stop the flow through these holes to prevent further degradation. Since the plant provides a great source of power and revenue for the region, it was determined that solutions for plugging the holes that would allow the plant to maintain its normal generation schedule each day would be necessary. The generation schedule allowed for 8 hour shutdown periods each night. This meant that all equipment involved with the hole plugging would have to be inserted, operate, and be removed from the shaft during each 8 hour period so that the plant could operate each day.

Hole with Protruding Material from Initial Inspection

Hole with Protruding Material from Initial Inspection

The access to the area where the holes were located was through the top of the surge shaft. The surge shaft at the Tala facility is located underground and is accessible through a tunnel. The surge shaft is approximately 180 meters in height with approximately 100 meters of water depth under normal operating conditions. Because the rate of flow through the bottom of the surge shaft is around 10 meters per second under normal operating conditions, it was determined by the owner that all materials involved with the hole plugging project would need to either be securely and permanently fastened in each hole or would need to completely be removed from the surge shaft each day prior to the scheduled generation. They required a solution that did not introduce unnecessary hazards that could flow into the penstocks and risk damage to the turbines.

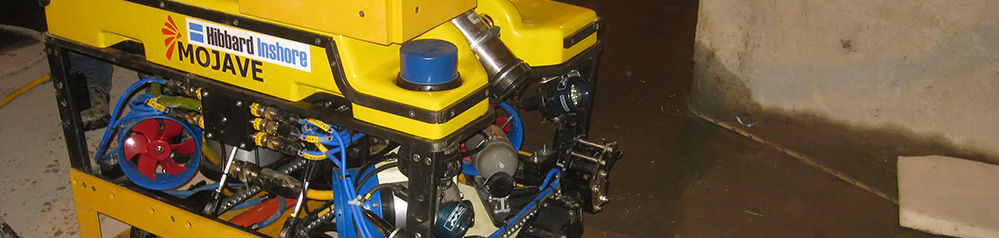

Hibbard Inshore 5 km Sub-Atlantic Navajo and 2 km Seabotix LBV for Initial Inspection

Hibbard Inshore 5 km Sub-Atlantic Navajo and 2 km Seabotix LBV for Initial Inspection

A project of this exact nature, to the team’s knowledge, had not previously been performed without manned entry. In this case though, it was determined that the costs and risks of a manned entry to make permanent hole repairs without dewatering at 100 meters of water depth, with the restriction of 8 hour outage periods, confined location, and the high flow rates in between outages would be prohibitive. Due to the short outage times, the confined nature of the work, and the depths involved, it was determined that utilizing an ROV provided both safety and economic benefits over attempting to use a commercial dive team.

Hole with Particulate Flowing through Surge Shaft Floor

Hole with Particulate Flowing through Surge Shaft Floor

Upon conferring with the Hibbard Inshore team which included Dr. Ray Henn of The Colorado School of Mines and Brierley Associates, the first option that was discussed was to devise a method to pump grout from the surface into each hole while leaving the shaft flooded. In this scenario, the Hibbard Inshore ROV would be able prepare each hole for grouting by clearing it of debris using an onboard saw and a hydraulic drilling system. Once the hole was cleaned out, a customized grout packer would be inserted to allow the ROV to attach the grout hoses from the surface and the grout to be pumped into each hole.

It was determined that an approach including grout pumped from the surface would be very risky due to the fact that it was unknown how large of a void exists underneath the surge shaft slab. Because of this, it was unknown how much grout would be needed to sufficiently fill each hole. It was also unknown as to whether each of the holes communicated with the others under the shaft. Worries were that the grouting would need to be performed very quickly in a single 8 hour shift at each hole so that the grout could properly set and that pressure differentials would need to be closely monitored to avoid placing forces on the slab that would result in a potential disaster due to cracking or heaving.

It was decided that the engineering issues for grouting were going to be complex. Understandably, the owners were looking for a lower risk option that could be completed quickly to reduce or eliminate the flow through the holes. During this discussion time, through additional investigation, the owners identified the exit path of the water from inside the surge shaft and determined it exiting through the side of the mountain. This development caused concern that there could be undermining occurring and increased the importance of identifying a good method to plug the holes as soon as possible. Because of this accelerated timeline and the complexity of the grouting scenario, the grouting option was set aside in favor of providing customized plugs to fill each hole.

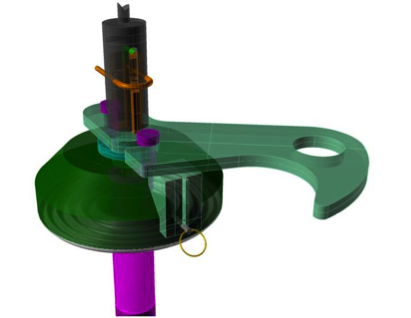

Packer CAD Model

Packer CAD Model

Upon deciding to plug the holes with customized plugs, it was determined that the concrete placed to create the slab at the bottom of the surge shaft was M20 concrete. This was important because it allowed the Hibbard Inshore team to determine that specialized plugs based on grouting packers could be placed into each hole and inflated to complete a seal without damaging the concrete. It was not known whether the holes were lined with pipe or if the seal would need to be made directly with the concrete; so, the team tested to insure that the plugs would work in either scenario.

The packer plugs were specially designed to be inserted by the ROV, to have the water hoses for plug inflation hooked up and unhooked by the ROV, and then to be secured into place by the ROV filling them with epoxy. Each packer plug was made from stainless steel and was coated in vulcanized rubber to provide a sealing surface. The packer plugs were specially designed in order to create a seal while not exerting forces that would exceed the compressive or tensile strengths of the concrete. In addition, the design considered that the plugs should require great force to remove them from each hole as they were meant to be a long term solution, and they would be in place during the high flow conditions caused by normal generating operations. After discussion of other possibilities, it was determined by the owner and construction company that this was the best method for repair, and the Hibbard Inshore team was hired to design the packers with Baski Inc. of Denver, Colorado so that they could be inserted by the Hibbard Inshore Sub-Atlantic Mojave ROV.

Packer Final Construction

Packer Final Construction

The packer plugs were designed, fabricated and tested in the Baski facility under the direction of Hibbard Inshore and Dr. Henn, and were shipped to Bhutan for installation in early April of 2012. Several sets of packers were manufactured in order to account for the possibility of varying sizes of holes. The hole sizes were estimated from the previous inspection, but it was not known how the holes might have changed since that time, and due to the urgency of the project, the owner, construction company and Hibbard Inshore all agreed that Hibbard Inshore should come prepared for a variety of scenarios.

Figure 9 Packer Cap with Floats for Retrival after Disconnect

Figure 9 Packer Cap with Floats for Retrival after Disconnect

Upon arrival at site, the Hibbard Inshore ROV was deployed to first measure the holes to determine if there had been any noticeable change from the previous inspection in 2011. The ROV was deployed to the bottom of the surge shaft, and measured each of the holes to confirm that they had not changed in size or nature since the previous inspection. Upon confirming the current size of each, the proper packer sizes were selected for each hole, and the ROV set forth to prepare each hole to receive its own packer plug. This preparation included inserting a measuring tool into each hole to determine if there was anything blocking the path of the packer as the packers had a minimum insertion length required to make a proper seal. Differential pressure tests were performed to evaluate communication between the holes and learn more about the nature of the leaks. A ROV operated drill was brought in case any of the holes needed to have lodged debris cleaned out, and a ROV operated saw was also brought because the initial inspection showed that one of the holes had a piece of protruding material sticking out that might have required sawing.