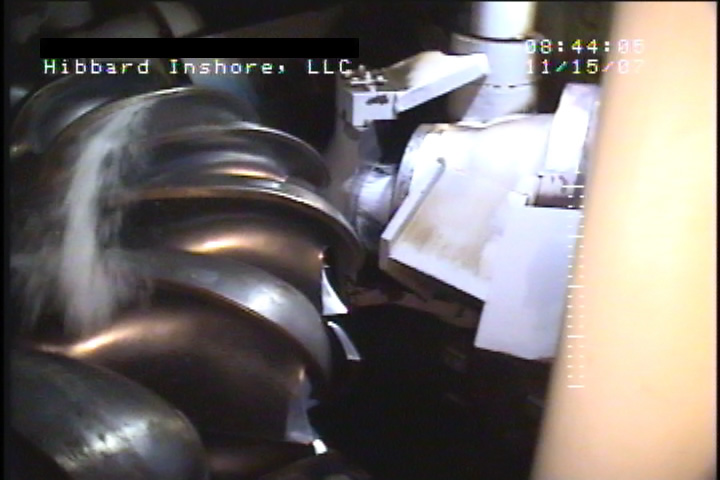

Internal Turbine Needle Valve Inspection

For this project, the customer suspected that incorrect operation of the needle valve and deflector plates in their Pelton turbine were causing a scenario where upon shut down, the turbine had the potential to reverse direction. This was a theory, but they wanted to commission an inspection to determine if that truly was the case so that they could take corrective action. The customer had previously worked with Hibbard Inshore on a number of penstock inspections and called them due to their extensive experience with underwater inspections. Hibbard Inshore devised a solution to allow video of the turbine to be taken during startup and shutdown. They were able to mount the same underwater cameras used on their ROVs to be placed inside the turbine during start up. The cameras were mounted in such a way as to be able to visually confirm the behavior of the needle valve and deflector plates, and upon turbine shutdown it was seen that indeed the deflector plates were deflecting some of the water in the opposite direction as intended. This allowed the customer to properly retrofit the system so that the turbine would not continue to reverse in fast shutdown scenarios.