ROV Cleaning of an Aqueduct Sump and Pouring of a Concrete Plug to Abandon a Shaft

A large city in the United States wanted to abandon a historical dewatering shaft adjacent to a shaft in one of their main aqueduct lines. The dewatering shaft communicated with the aqueduct shaft via a valve near the bottom of the sump portion of the aqueduct shaft, and the valve had ceased to operate over time. In order to abandon the dewatering shaft properly, the sump of the aqueduct shaft would need to be cleaned down to the concrete, and a concrete plug would need to be poured to close the existing valve. Once that plug was in place, the dewatering shaft could also be filled with a concrete pour. The difficulty in this situation is that the aqueduct shaft could not be dewatered, the water depth was over 300 feet deep, the shaft height was approximately 400 feet in total, and the shaft had a restriction such that it was too small for a commercial dive team to pass through with appropriate equipment to work at those depths.

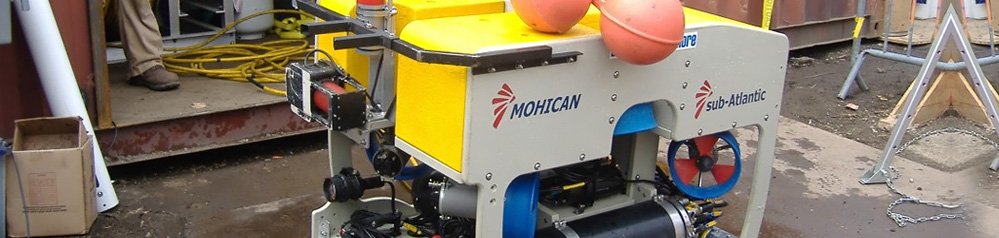

Hibbard Inshore developed a solution for their Mohican ROV with sonar and appropriate tooling to assess the sump, to clear the sediment and debris present, and to monitor the concrete pour of the plug in zero visibility conditions.

Hibbard started with a sonar and video inspection on the shaft to assess sediment buildup and debris. The large pieces of debris, including large timber, were then removed by the ROV using its manipulator arm and a variety of rigging. In addition to removing the large items, the ROV guided the suction hose of a high head pump that was able to remove the sediment in the sump to the surface where it was then transported to a permitted disposal site. The sump was monitored during the sediment removal by the ROV’s sonar to continually look at the sediment depth versus the as-built drawings to confirm that the sediment was fully removed.

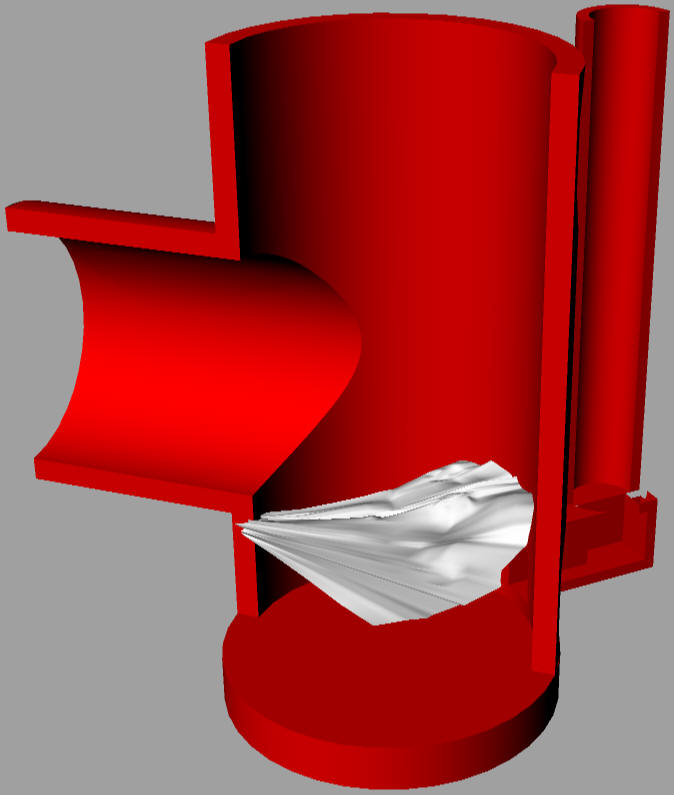

Following safe disposal of the sediment and debris, the trash pump was replaced with the equipment to pour the concrete plug. The ROV used its sonar to monitor the concrete placement in real-time as the plug needed to cover the entirety of the existing valve without restricting the lateral aqueduct pipe. This meant that the elevation of the plug pour had to be precise and the concrete pour would need to be cut off at exactly the right time to keep the pour elevation above the valve and below the invert of the lateral pipe (See CAD Model). The ROV allowed Hibbard Inshore to do this as the sonar could accurately measure the level of the pour as it was occurring.

In addition to the concern about the plug height, the depth of the pour lead to a concern that the concrete would separate and not solidify. Because of this, Hibbard Inshore could not use a traditional tremie method to place the concrete and instead needed to devise a method to pump a mixture of concrete that would not separate. The concrete pour hose needed to be slowly extracted and maintain a precise height off of the bottom as the pour began to rise at the bottom of the shaft. Because the pour restricted visibility, the ROV’s sonar allowed the onsite crew to also coordinate the lifting of the concrete pour piping.

Finally, after the concrete plug was in place and had sealed off the valve connecting the two shafts, Hibbard Inshore was able to move the concrete pumping system to the adjacent dewatering shaft to complete a continuous 400 foot pour to completely fill and decommission that shaft. The inspection, dredging, debris removal and concrete services were all successfully performed by Hibbard Inshore, demonstrating the ingenuity of their team and the flexibility of their ROVs to perform a complex construction project in a deep water, confined space with limited visibility.