Debris Removal and 3D Dimensioning of Underwater Intakes for Valve Replacement

The underwater portions of hydroelectric dams present a number of unique challenges when it comes to operations and maintenance. Until the 1980’s when the first commercially available remotely operated vehicles (ROVs) started to come into use, the only options for inspecting or maintaining these portions of the dams were to dewater them or to use commercial divers where safe and possible.

As time has gone on, the underwater operations and maintenance tasks at many facilities are becoming larger in scope as the existing hydroelectric infrastructure continues to age. After years of operation, these facilities can begin to deteriorate without proactive repair and maintenance programs. With the large investment required to build a new hydroelectric project, generating companies generally consider all possible avenues to extend the lifespan of existing assets, and while repairs to some of the assets require routine operations, the assets that are underwater or under pressure are often more difficult to address. Because these underwater assets are critical to the ability to generate power, control flow, address associated environmental concerns including fisheries and recreation, and maintain profitability, maintenance to these assets can often cause outage times or other undesired effects.

Figure 6 Navajo to Guide Dredging with Suction Tube

Figure 6 Navajo to Guide Dredging with Suction Tube

As with other major repairs, in the past, the only options to replace these valves or gates were to dewater the dam or take the risk of working on live pipes under pressure. While dewatering is effective in terms of allowing a specific repair to be made, it is a process that is often lengthy and is high in cost due to the outage times required and/or the requirement to build a coffer dam. These costs are in addition to the concern of placing stress on the whole structure when hydrostatic pressure is removed causing higher potential for cracking or collapse. Because of these, today, dewatering is often a method of last resort as is working on the pipes under pressure. Working under pressure for these types of repairs can be highly dangerous to both the workmen involved and the facility itself. Because of that, those methods are most often considered impractical.

To avoid dewatering at hydro facilities, many repairs can be accomplished by using experienced commercial dive teams with the latest in underwater tooling. These teams can work very effectively, particularly in lower head situations, and can perform a great number of maintenance operations. However in terms of many of the gates and valves we are talking about here, the use of commercial dive teams can become both costly and dangerous due to a combination of the very high head pressure and the confined nature of the location of the tunnels and pipes leading to these gates and valves.

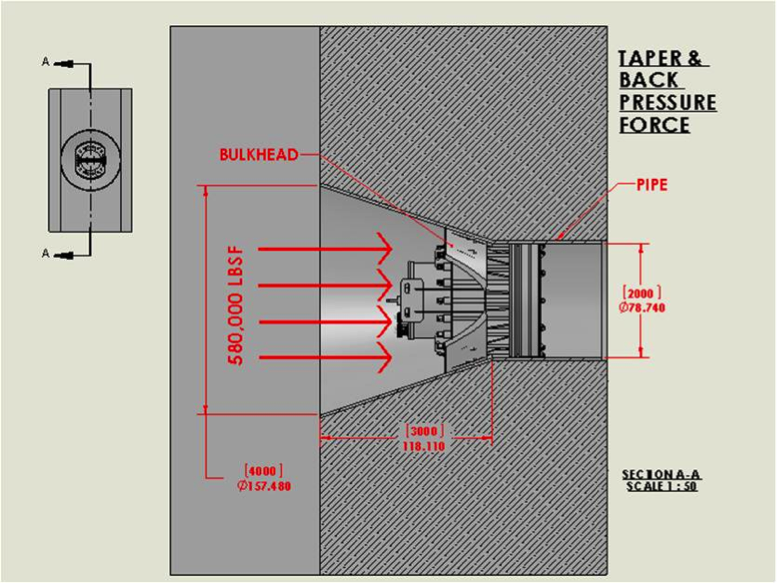

This project was the first phase of a solution that has been developed by Hibbard Inshore in conjunction with their customers to address these issues, the remotely operated vehicle (ROV) insertion of temporary mechanical bulkhead plugs. These plugs are built to the specific dimensions of the pressure piping, have multiple seals for redundancy and safety purposes, can be inserted into the upstream, underwater side of the piping by an ROV, can be monitored continuously throughout the project from the surface, and can be removed at the conclusion of the project. These plugs allow a seal to be made in the pressure piping that will allow just the section of piping downstream of the plug to be dewatered for the replacement of the valve or gate. This is a tremendous savings in both time and cost over dewatering the entire intake structure, and it can be accomplished without putting people in harm’s way.

Figure 4 Navajo with Jetting Tip

Figure 4 Navajo with Jetting Tip

This project was at a dam in Spain that has traditionally been used as an irrigation and water supply dam. The dam was built with two intakes fed through a concrete structure on the upstream face of the dam leading around a 90 degree bend and into two sections of two meter diameter steel lined concrete pipe. The intakes were at approximately 185 feet of depth. These pipes are conical at their mouths and neck down to a two meter diameter. The dam owner realized that they would need to replace the existing valves in order to properly feed the turbines because the existing valves had aged and were no longer fully operational. They considered all of the methods detailed earlier including, diving, dewatering, and replacement of the valve under pressure and came to the conclusion that because the intake pipes were in a confined area and diver safety was a concern, an unmanned method needed to be designed to get a plug in place that would allow the downstream portion of each pipe to be dewatered for valve replacement. It was decided through discussion with Hibbard Inshore that placing a temporary plug with an ROV was a viable method.

Once it was decided that the ROV placement was viable, the line of questioning turned to determining the current conditions in the intake as it had not been examined in many years. This meant determining if sediment and debris needed to be removed for the plugging, establishing current dimensioning of each pipe to be plugged to allow for the plug design, determining if there was any variance from the as-built drawings, and determining if the structures could withstand the change in pressures that would occur during the plugging of one or both pipes.

It was agreed upon by Hibbard Inshore and the dam owner that the project would be split into two phases. The first phase would be discovery to confirm the viability of plugging by using an ROV to take observations and data on the structure. Data would be gathered to complete the design and manufacture of the plug or plugs and to help engineers make a decision whether one or two plugs would be used. The second phase would involve any remaining debris removal necessary for the plug insertion along with inserting and monitoring the plug to ensure a proper seal during the valve replacement. This was also a cost effective way of approaching the project as the initial inspections can be conducted with a small ROV (in this case a Sub-Atlantic Navajo), and the bulkhead insertion would require a larger, more costly ROV for power purposes (in this case a Sub-Atlantic Mohican).

Figure 1 Navajo ROV with 3D Sonar Head

Figure 1 Navajo ROV with 3D Sonar Head

During the initial discussions of the project, concerns were that pressure changes might wrinkle or collapse the pipelines if the structure was degraded, and that the bulkhead plug would not have a single point of failure.

To address these concerns for the first phase, Hibbard Inshore brought a small inspection class ROV with a variety of tools to accomplish the discovery on site. In addition to standard video, dual sonar units were added to the vehicle to allow it to navigate and dimension in the forward looking direction and to take cross-sectional profiles once in the intake. This 2D dimensioning was good for quick dimensional confirmation. In addition to the 2D sonar, the vehicle also was outfitted with a 3D sonar unit so that an accurate CAD model could be generated of each pipe. This assured that any anomalies in the shape of each pipe would be accounted for in the plug manufacturing. This was deeme=d to be highly important since creating an impenetrable seal with the plug would be necessary for the safety of the valve replacement workers. The final sensor that was used with the ROV was an ultrasonic thickness sensor to confirm the steel thickness of each pipe so that engineers could make the determination of whether the steel in its current condition was suitable to withstand the forces generated by a partial dewatering. If the steel had corroded too significantly, the pipes could buckle or collapse entirely during the sealing and dewatering process. In addition to the sensors, the ROV was outfitted to be able to guide dredging equipment and carry a jetting nozzle in case the intake was full of sediment as the intake had not been operated in quite a while and was on the bottom of the reservoir.

Sediment Being Pumped from Reservoir Bottom Using Navajo ROV

Sediment Being Pumped from Reservoir Bottom Using Navajo ROV

The decision to bring the sediment removal equipment proved to be a good one as approximately 50% of each pipe was filled and needed to be cleaned out by the ROV prior to dimensional data and thicknesses being taken. The sediment was removed from site to comply with environmental policies, and each of the pipes was cleared for inspection. Once the 3-Dimensional sonar measurements and thickness measurements were taken, it was determined that the method of choice would be to use a single, conical shaped bulkhead that would be placed in one of the pipes, provide triple redundant sealing, provide the ability to monitor pressure, and be inserted and removed solely by an ROV without any men in the water.

Rendering of Conical Bulkhead Plug to be Inserted by ROV for Sealing in Spain

Rendering of Conical Bulkhead Plug to be Inserted by ROV for Sealing in Spain

The bulkhead would be inserted in one of the pipes, the valve would be replaced, the bulkhead would be removed, its seals would be replaced, and the plug would then be inserted in the second pipe. The issue of defining a method for repair and associate cost that could be budgeted for the customer’s problem had been solved.