Long Flooded Sewer Siphon Inspection

Hibbard Inshore performed an internal siphon inspection of wastewater pipeline to determine the existing condition of the pipe and to note any features of interest. The inspection was a challenge for traditional sewer inspection systems because the siphon was over 240 feet deep and was over 2900 feet in length. Because this was an influent pipeline, it was assumed that there would be material buildup at the elbows of the siphon making it even more difficult for a crawling system to inspect. As a result, it was decided that the siphon would be inspected with Hibbard Inshore’s Long Range Navajo vehicle with 7,200’ tether. Flow to the pipe was temporarily stopped to perform the inspection allowing some of the particulate to settle out of the water and giving the ROV cameras limited visibility.

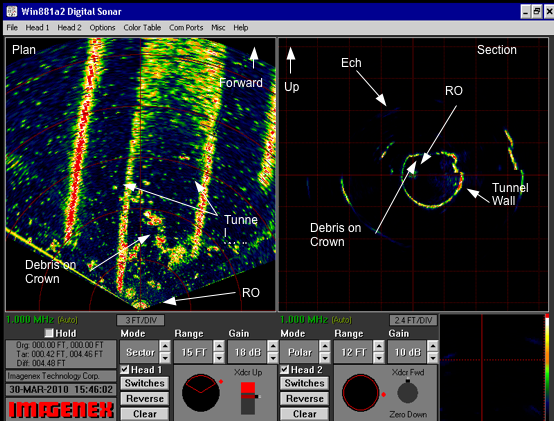

This sonar plot details the large section of buildup found on the crown of pipeline.

This sonar plot details the large section of buildup found on the crown of pipeline.

Hibbard Inshore commissioned their Navajo Remotely Operated Vehicle (ROV) outfitted with monochrome and color video cameras and two types of sonar to perform the inspection which was completed from two access points with the vehicle traveling through the line in both the upstream and downstream directions until there was overlap. This was done because the line had a significant bend of almost 90 degrees present that would cause significant friction for the umbilical. Therefore, the vehicle inspected to just past this bend from the upstream direction, and then on a subsequent day inspected the pipe to just past the bend from the downstream direction. During the inspection the Navajo stopped every 50 feet to get a stationary sonar plot with a cross section in order to measure sediment levels and to determine if there were any out of round conditions in the pipe. The water clarity was good enough once the pipe was dormant for a period of time that video was periodically used to see features such as spalled concrete, pipe joints, exposed wire mesh from the pre-stressed concrete cylinder pipe and the character and volume of debris. The sonar was used to detect features such as open joints, sedimentation, and grease buildups in the line and to measure cross-sectional dimensioning to quantify the sediment and buildups allowing the owner to assess the condition of a line that had not previously been able to be inspected.