Inspection of Newer Hydroelectric Facilities

In 2010, due to equipment capabilities and previous inspection experience at hydroelectric plants, Hibbard Inshore was hired to inspect two facilities in Bhutan. Hibbard Inshore used two of their specialized ROVs equipped with video cameras and multiple types of sonar to complete the inspections. The purpose of these inspections was to look at the underwater structures of each plant to determine how well they were holding up after they had been commissioned. While one of the plants, Chukha Hydro, had been in operation for some time, the owner also decided to proactively inspect their newer Tala Hydropower Plant. While both facilities had been inspected prior to commissioning, the owner thought it prudent to also inspect them now that they had been operating to determine whether any conditions of concern were present after the introduction of water. This would be the first inspection of these structures since they had been filled.

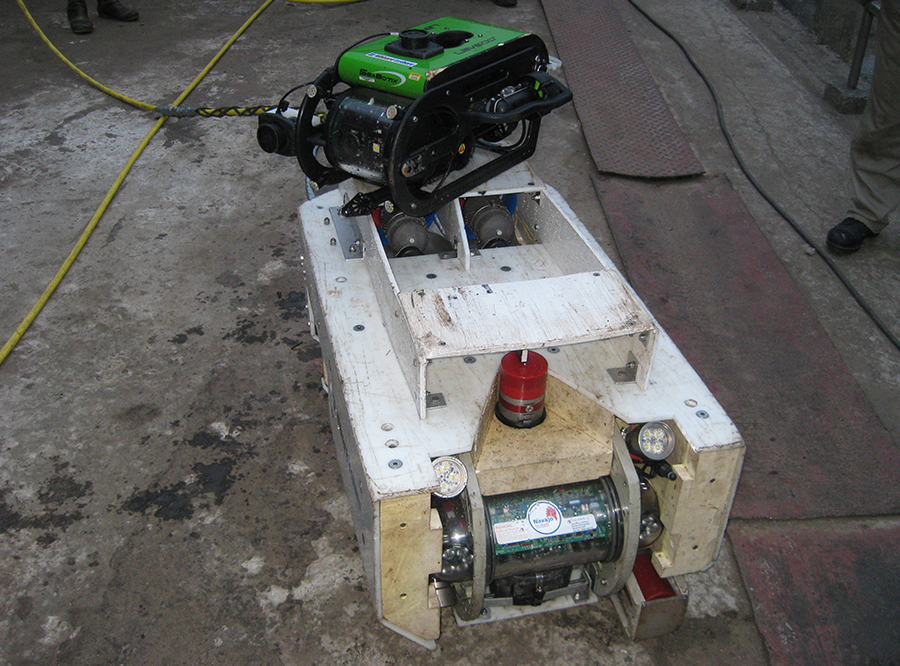

Figure 1 Hibbard Crew with Long Range Navajo (white) and LBV (Green)

Figure 1 Hibbard Crew with Long Range Navajo (white) and LBV (Green)

In order to perform the inspections, Hibbard Inshore used two ROVs, a Long Range Sub-Atlantic Navajo with 5 kilometers of tether and a 600 meter depth rated LBV600-6. The combination of these two vehicles allowed Hibbard Inshore to inspect the internal portions of each plant’s underwater structures to look for signs of wear and degradation such as concrete spalling, out of round conditions, cracking, holes, sediment buildup, and debris. During the inspections of the head race tunnels, surge shafts and pressure piping, the Hibbard Inshore ROV saw several small anomalies that were considered “areas to watch” for the future to make sure further degradation wasn’t occurring, and the ROV detected several small holes in the concrete in the bottom of the surge shaft at the newer Tala Facility. After observation with the ROV cameras, it was clear that particulate in the water was being sucked through each of the holes meaning that there were flow paths from inside of the Surge Shaft to underneath the structure. This finding was of great concern to the future stability of the structure. This allowed the dam owner to work with Hibbard Inshore on a plan to permanently plug those holes in 2012 and 2013.